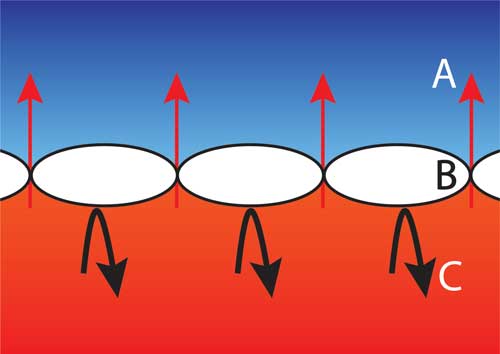

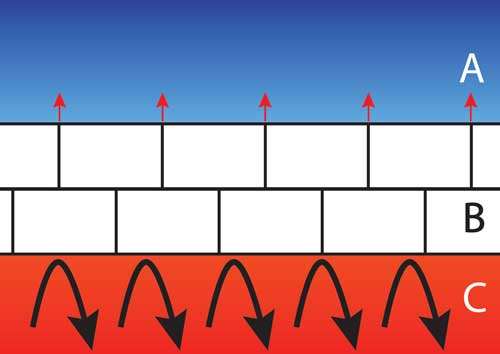

Stitched Through Baffles

The simplest baffle design is called Stitched Through. This is the easiest and lightest baffle to manufacture. However, heat is lost through the stitching and the down does not loft as efficiently around the edges of the baffles due to the lack of a sidewall. A sidewall allows for spaceto be better used enabling the down to loft and, therefore to insulate more efficiently.

Stitched Through Baffles are normally only used on cheaper sleeping bags or extremely lightweight sleeping bags and sleeping bag quilts.