Polish Goose Down Insulation

Goose Down is a pure, natural, thermal-insulation product. It is grown by birds and in cold climates it enables them to survive severe weather conditions. The best down, therefore, is to be found on birds which spend winters in arctic or sub-arctic conditions.

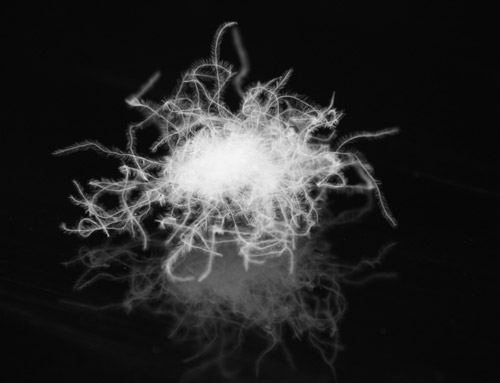

Goose Down is unlike normal feathers in that it grows without a hard, central “stalk” or quill. In mature birds it forms a soft, fluffy underlayer close to the body beneath the bird’s main feathers. The most common sources of down are ducks and geese. Down is used as an insulating material in various man-made products such as sleeping bags, insulated jackets, and bed coverings.

Criterion down is sourced from Poland. Poland is a member state of the EU where live plucking is illegal and has been so for a number of decades. Other parts of the world do not have as stringent animal husbandry/welfare laws as in the UK and Europe. Our supplier of down holds both the Responsible Down Standard (RDS) and the Downpass Down Standard.

Understanding Down Quality

Down quality varies and there are a number of ways in which a reputable company can indicate down quality to you. This is done by displaying the fill power (FP) and down-to-feather ratio, they should also tell you how much down is actually in the sleeping bag.

Understanding Fill Power (FP)

Down insulates by lofting and trapping warm air such as body heat. To measure loft down is subjected to a test which measures its Fill Power (FP). The Fill Power test denotes the volume (in cubic inches) to which a measured weight of down will expand when it takes in air. The greater the Fill Power, the greater the expansion and all things being equal the warmer the sleeping bag.

When buying a down item you will most often see a 3 digit number followed by FP, for example 850FP. The higher the number the better the down is at insulating, essentially meaning the lighter the product.

Fill Power is the most often used guide as it is simple to understand. However understanding how warm a down product is much more than looking at Fill Power. You have to take into consideration the quantity of down as well as the size of the product.

For example, 100g of 700FP will not insulate as well as 100g of 850FP down, but 200g of 700FP down may. This is worked out by calculating the fill volume which is explained in a following section.

For example, the two sleeping bags below have the same amount of down (350g) they both have 60/40 differential fill with boxwall baffles on the base and trapezod baffles on the top of the bag. Yet one has a comfort temperature of -3°C and the other is -6°C. In this case the difference is mainly from the Quantum 350 using 850FP down and the Ultralight 350 using 700FP down.

-

Criterion Ultralight 350 Down Sleeping Bag

£215.00 3 Season-3°c765gSelect options This product has multiple variants. The options may be chosen on the product page

-

Sale!

Criterion Quantum 350 Down Sleeping Bag

£325.00Original price was: £325.00.£300.00Current price is: £300.00. 3 Season, 4 Season-6°c695gSelect options This product has multiple variants. The options may be chosen on the product page

The Down To Feather Ratio

The second way of demonstrating down quality is the Down to feather ratio. At slaughter down and feathers are collected together, cleaned and sifted. A 100% down product is possible but in the real world completely uneconomical. The down to feather ratio shows the amount of down and feathers within a product. Therefore knowing this ratio helps understand the quality of the down. A 95:5 ratio of down to feathers indicates much higher quality down than a 70:30 split. Due to automation the lower the percentage of feathers in the ratio will also mean that the feathers are smaller and finer, so your are much less likely to encounter hard quills.

The down to feather ratio is used much less than Fill Power, because generally the higher the fill power the high the down to feather ratio.

Fill Volume

Fill volume is a measure of how much the total of all the down in a particular sleeping bag will expand. The greater the fill volume, the warmer the sleeping bag.

The ability to loft a sleeping bag depends on the weight of down that it contains and on the fill power or quality of the down being used. A comparison between sleeping bags can be done using the equation:

(weight of down in grams) divided by 30, multiplied by the fill power

For example, 100g of 850FP down would have the following fill volume

(100g/30)*850 = 2833 cubic inches

100g of 700FP down would have the following fill volume

(100g/30)*700 = 2333 Cubic Inches

For a 700FP bag to have the same fill volume as the 100g example of 850FP down we would need (2833/700)*30 = 121g of down.

The example above shows how a sleeping bag with a higher fill power can have less down yet still be advertised at the same temperature rating as a bag with more down of a lower quality.

When comparing the temperature or “season” ratings quoted by different manufacturers it is worthwhile doing the above type of calculation and comparing Fill Volumes. Please note, whilst this is a useful guide this does not take into account the size of the bag. Its baffle construction or the distribution of down between the base and top.

Please remember that the comfort temperatures quoted by most sleeping bag manufacturers are a very subjective measure (different people can tolerate different levels of cold).

However, it should be borne in mind that good design also has an effect and, for example, a sleeping bag which utilises a Trapezoidal baffle construction will have a comfort temperature rating of 2 to 3 °C lower (better) than a sleeping bag containing the same quality and weight of down, but constructed using the Boxwall method.

Other constructional design features also have an effect. The better the overall design the lower the risk of “cold spots” arising when a sleeping bag is being used.

Technical Note – temperature ratings and overall weight

1. The effectiveness of insulation materials is affected by moisture. You will feel colder in your sleeping bag in high humidity conditions. Moisture will also add to the weight of a sleeping bag.

2. How warm you feel is also dependent on where you are sleeping. The size of the body of air surrounding the sleeping bag and the amount of air movement/ventilation both affect heat retention.

The comfort temperatures that we quote for Criterion sleeping bags assume that they are being used in average humidity conditions inside typically-sized 1 to 3-person tents (with a relatively small body of still air surrounding the sleeping bag).

DOWN VERSUS SYNTHETIC INSULATION

Down is a better insulator than the best synthetic materials, “weight-for-weight”. It is lightweight with excellent loft yet is extremely compressible to give a small pack size.

However, down is a poor performer when wet, unlike many synthetic fibres which resist moisture well. Synthetics are generally heavier and bulkier and with a much shorter life-span than down.

Down’s greatest advantage, however, is its versatility as regards temperature conditions. Down sleeping bags have a wider spread of comfort temperature than synthetics, For example, a down sleeping bag with a comfort temperature rating of -15°C will still be comfortable when used at 0°C, whereas a synthetic sleeping bag rated at only -7°C could be too warm at 0°C. Anyone planning to use a sleeping bag at different times of the year in a variety of temperature conditions should consider using a down sleeping bag first and foremost.

GOOSE DOWN OR DUCK DOWN?

Most down is sourced from ducks due to food demand. With the exception of ducks such as Eider Ducks, duck down is not as good as goose down. Duck down does not stay lofted as long as goose down and typically does not last as long. Even if the fill power is the same the goose down will last longer.